FIRE SEAL Hood

Specifications

Innovative outer materials

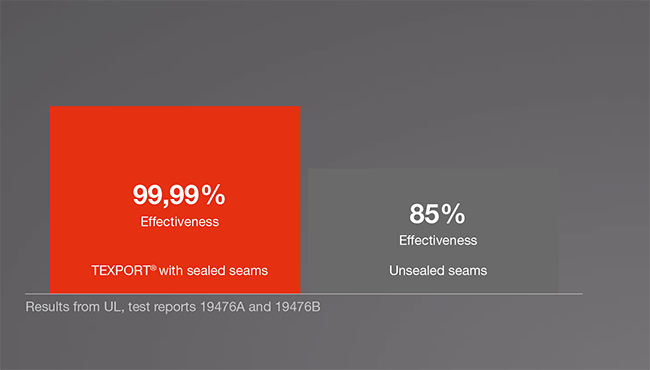

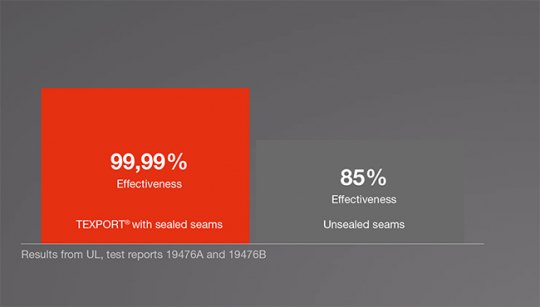

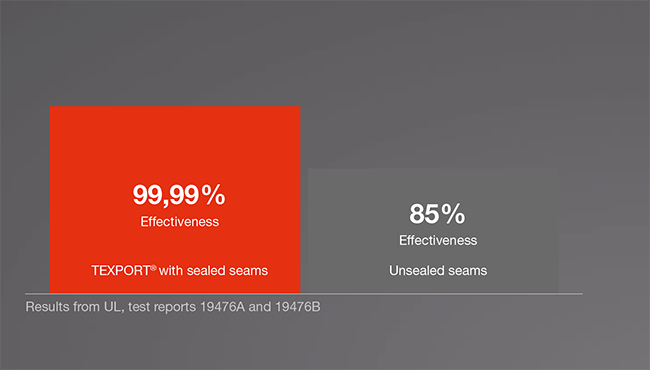

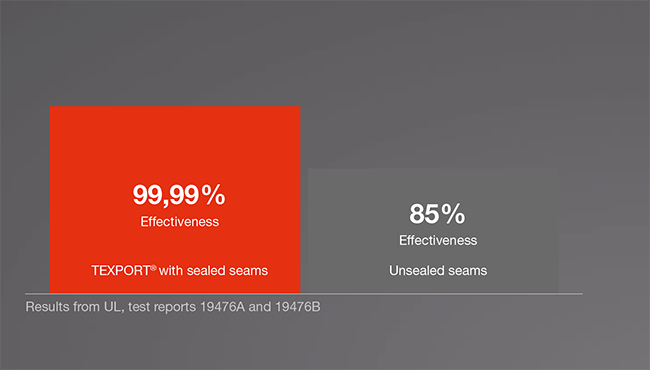

The area of a particle barrier is an effective filter for particle sizes from >0,1 μm to >0,2 μm. This means the particle barriers used provide optimal protection against penetration by dangerous harmful substances such as polycyclic aromatic hydrocarbons (PAH). As the saying goes, a chain is only as strong as its weakest link. And the weakest link in these particle barriers are the seams. A sewing needle has an average thickness of 0.9 mm to 1.1 mm (1 mm = 1000 μm). The hole that a sewing needle makes in the particle barrier is thus 10,000 times larger if the filter effect is >0,1 μm. Since the dividing seams on the hoods are almost exclusively executed with flat seams (to prevent pressure marks), the untight points double. The smaller the cut portions which make up the hood are, the more weak points the hood will have. To obtain a sustainable test, TEXPORT® developed a testing device (no laboratory standard), in order to get proof of the tightness of the particle barrier seams quickly and easily. In video c mparison, this is proven quite impressively. 85 % Effectiveness Unsealed seams 99,99 % Effectiveness TEXPORT® with sealed seams Fig. Fire Seal PP 3ly short, O A 10, 004 in combination with Fire Survivor-Jacket, ZA16, 203 (example) The perforated seam hole is in part filled in with thread. This cannot really be called seam-sealing though. On the contrary: If the seams are stretched when taking the hood off or putting it on – which is unavoidable – the seams will be stretched by the pulling force acting on them and the seam hole will open wider. For this reason, the greatest possible attention must be paid to finishing the particle barrier’s seams during manufacturing. In contrast to its competitors, TEXPORT® takes a different road in manufacturing flame-retardant hoods. TEXPORT® is the only manufacturer which seals all seams of the particle barrier with a seam sealant. This assures that the particle barrier of TEXPORT®-flame-retardant hoods guarantee an effectiveness of 99 99 % (NFPA 1971-2018) at the intersecting seams even after 50 washes.

To create a perfect and comfortable combination of firefighter’s protective jacket and flame-retardant hood, TEXPORT® developed a shorter-form flame-retardant hood.* The Fire Seal flame-retardant hood covers 100 % of the jacket’s open collar and this new construction achieves a wholly new, optimized protection parameter. The new construction provides a perfect overlap of the collar opening – in contrast to conventional flame-retardant hoods. This prevents harmful particles from getting inside the jacket’s interior between the hood and collar. A slip-resistant band on the end of the hood assures that it will sit perfectly on the jacket collar.

To demonstrate the difference in effective protection, TEXPORT® compared its particle barrier with seam sealant and without seam sealant (tested at the intersecting seams). The result was impressive.

To obtain a sustainable test, TEXPORT® developed a testing device (no laboratory standard), in order to get proof of the tightness of the particle barrier seams quickly and easily. In video comparison, this is proven quite impressively.

TEXPORT® Fire Hoods test device

I accept the use of cookies which are essential for the function of the website (essential cookies), to offer me products and services which match my areas of interest and which make it possible to generate statistics (performance cookies) as well as those enabling me to access customised products and services on the website (marketing cookies). I can revoke my consent at any time. If you do not want to consent to these, we will limit ourselves to using the essential cookies and the contents will not be customised for your use. You can find additional information here. You can change your settings at any time by calling up the Cookie Settings at the top of the page